|

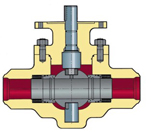

Top Entry Valves

Top entry ball valves are of rigid body design and allow easy access to the internal area. Suitable for all topside and subsea applications. Subsea duty Top Entry Ball Valves for Statoil Norway. Manufactured in Duplex material, they have a fifty year design life and conform to API 5000.

.jpg)

Main Features

- Choice of soft or metal-to-metal seated designs

- Anti-blowout stem design

- Full, exact or reduced port configurations

- Anti-static design

- Two piece or three piece body

- Fire safe certified design

- Piston seats for gas tight, bubble tight shut off

Top Entry Ball Valve

|

Ratings: |

ANSI Class 150 through to API Class 15000 |

|

Sizes: |

50 to 1050 mm (2 to 42 in) |

|

Body Materials: |

Carbon Steel, Stainless Steel, Duplex, Super Duplex, Hastalloy, Inconel, Monel, Titanium |

|

Trim Materials: |

From Carbon/ENP through Duplex/hardfaced to suit application |

|

End Connections: |

Flanged, butt weld, clamp ends, specials |

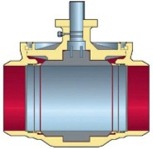

Split Body Valves

Split body ball valves are offered in two basic designs, trunnion mounted and floating ball.

Main Features

- Easy in-line access to all parts for maintenance

- Choice of soft or metal-to-metal seated designs

- Full, exact or reduced port configurations

- Fire safe certified design

- Block and bleed feature

- Piston seats for gas tight, bubble tight shut off

Split Body Valve

|

Ratings: |

ANSI Class 150 through to API Class 15000 |

|

Sizes: |

50 to 1050 mm (2 to 42 in) |

|

Body Materials: |

Carbon Steel, Stainless Steel, Duplex, Super Duplex, Hastalloy, Inconel, Monel, Titanium |

|

Trim Materials: |

From Carbon/ENP through Duplex/hardfaced to suit application |

|

End Connections: |

Flanged, butt weld, clamp ends, specials |

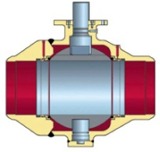

Trunnion Mounted Ball Valves

Trunnion mounted ball valves are bubble tight during shut-off. This is achieved by restricting the movement of the ball between the spring loaded upstream sealing seats. The ball is held in position by the stem and trunnion shafts. Initial seat load is provided by the seat springs to give low pressure sealing, after which, the system pressure loads the seats onto the ball when the valve is shut.

All Welded Ball Valve

All welded construction ball valves are designed to API 6A & 6D and are supplied in sizes up to 42 in and are of trunnion mounted design. They are suitable for all onshore, topside and subsea applications.

Advantages

- Fire tested to API 607/BS6755 pt 2

- Fewer leak paths

- Self relieving seats

- Block and bleed feature

- Anti-blowout stem design

- Full or reduced port configurations Top entry All Welded Ball Valve Split Body All Welded Ball Valve

- Secondary seat sealing system

- Non-lubricating design

|