What is a double block & bleed(DBB) monoflange valve?

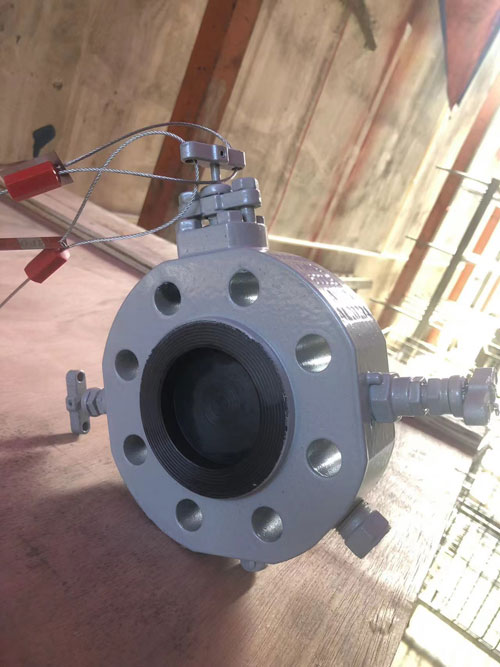

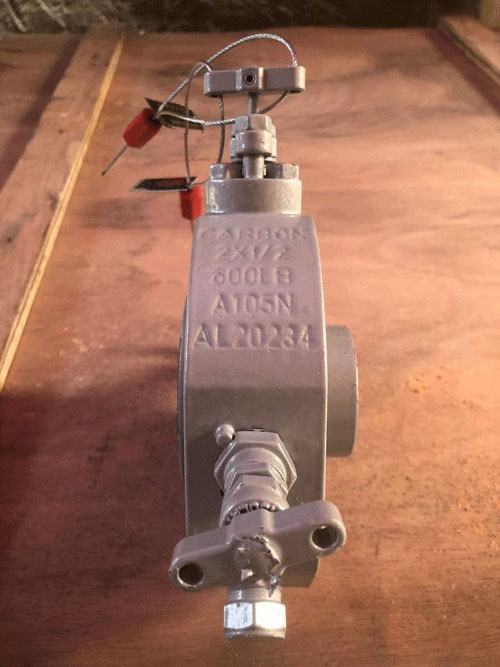

The double block & bleed(DBB) monoflange valve is a slimline valve with mono flange to incorpoerate the old valve system of several valves with multiple leak paths to deploy different shut off and pass ways. It can be made in forged steel A105/F316/F51 etc, its compact dimension allow it to be installed flexiblely with reduced cost and weight. The single valve with simple struture bring easy installation and maintainance.

How the double block & bleed(DBB) monoflange valve work?

The valve is drilled internally with several holes to connect to the annular valve chambers. The double block and bleed means 3 functions inside: 2 block valves and 1 bleed valves. Below picture demonstrate the valve working principle:

1- When the flow enters upward, it is stopped by the first shut-off valve[1];

2- When the first shut-off valve[1] open, the flow go to 2nd shut-off valve[2]; If [2] open, the flow go directly through the process line;

3- When the [1] closed, the flow jammed between valve and instrument can be discharged through the bleed valve[3]. As the 2 shut-off valves are in angled position so it allows the flow to pass through.

.jpg)