#singleactingpneumaticactuator #dobuleactingpneumaticactuator #springreturn #failopen #failclose #pneumaticactuatedbutterflyvalve

Single acting and double acting pneumatic actuators

For butterfly valve etc, the pneumatic actuator is widely used to drive the valve, so what is the difference between the commonly used actuator - Single acting and double acting pneumatic actuators?

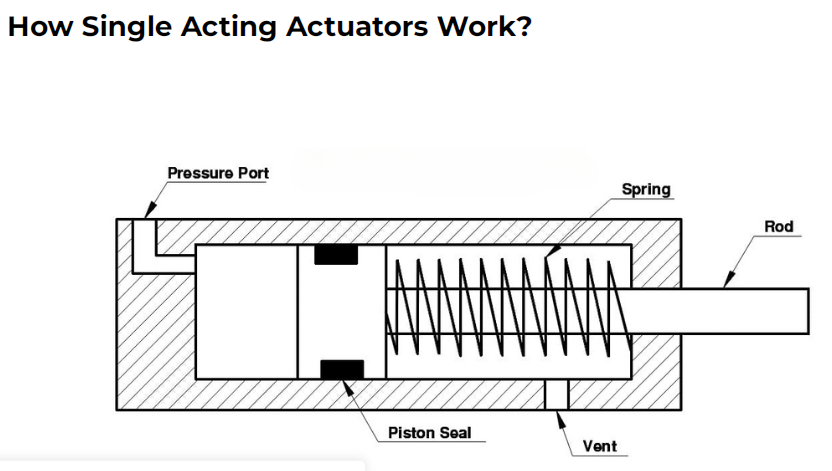

Single acting pneumatic actuator has spring return feature, suitable for dangerous enviroment.

Fail open: air charging to close the valve, air losing to return the open position;

Fail close: air charging to open the valve, air losing to return the close position.

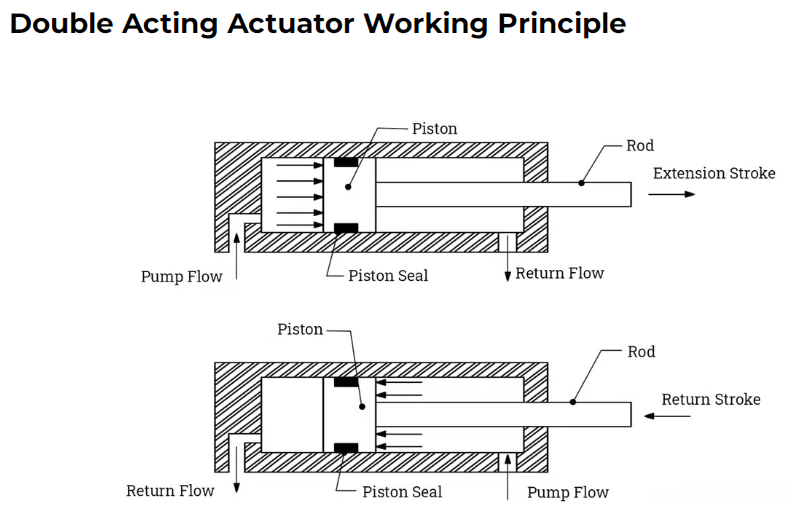

Double acting pneumatic actuator needs air charging for both opening and closing action. If air lost, the valve will retain the old position till air charging again. Normally used in accurately controling situations.

A Single acting pneumatic butterfly valve refers to a valve that only needs the pneumatic device to provide a gas source during the operation process.This valve is generally equipped with a spring mechanism to open the valve disc through air pressure, and when the gas source is disconnected, the spring will automatically reset the valve disc to the initial position. The advantages of Single acting valve are simple structure, convenient installation, and can quickly close when the gas source is disconnected, to prevent fluid leakage, suitable for occasions with high safety requirements. For example, in water treatment, chemical and other industries, Single acting pneumatic butterfly valve is often used for emergency cut-off or security guard.

In Single acting pneumatic butterfly valves, the choice of spring is crucial because it directly affects the response speed and closing strength of the valve. In order to ensure that the valve can be reliably closed when the gas source fails, it is usually necessary to design the specifications of the spring according to the nature of the fluid and the working pressure.

On the other hand, the double acting pneumatic butterfly valve refers to the gas source provided by the pneumatic device to complete the opening and closing of the valve during the operation process. Different from Single acting valve, the operation of double acting valve depends on the alternating act of air pressure, that is, the valve disc is pushed through the gas source to the open position, while the valve disc is pushed back to the closed position through the reverse gas source. This design makes the double acting pneumatic butterfly valve have higher flexibility and control accuracy, and can adapt to more complex working conditions.

The advantage of double acting pneumatic butterfly valve is that its valve movement is more stable, can achieve faster response speed, so in the need for frequent opening and closing or precise control of flow occasions, double acting valve is often a more ideal choice. For example, in pharmaceutical, food processing and high-demand chemical processes, double acting pneumatic butterfly valves can meet stringent operating requirements.

However, the disadvantage of double acting pneumatic butterfly valve is that the system is relatively complex, requiring more gas source pipes and control system. At the same time, when the gas source fails, the valve cannot be automatically reset, which may bring certain risks in some safety-critical applications.